Our impact on the climat

The current economic development policy of the EU places particularly strong emphasis on climate issues, specified in the European Green Deal, Fit for 55 Package and ancillary documents, which in effect signifies the requirement to transition the industry towards a low-emission economy.

In connection with the nature of its activity, the Group has direct and indirect impact on climate changes:

- DIRECT IMPACT on climate change results from mining and production operations:

- Greenhouse gas emissions related to the production process, mainly methane associated with the coal mining process (72% of the organization's CF value), carbon dioxide associated with the coking process,

- Greenhouse gas emissions associated with electricity and heat production,

- Fuel and energy consumption as part of conducted operations and the related greenhouse gas emissions.

- INDIRECT IMPACT on climate change is mainly related to the processes of production and transportation of raw materials, materials necessary for production processes and transportation of manufactured products, energy intensity of the production process and management of mainly mining waste.

RISKS AND OPPORTUNITIES ASSOCIATED WITH THE CLIMATE

As part of the Environmental Strategy, an analysis of climate risks and opportunities and their impact on the JSW Group's business has been conducted. The largest potential adverse impact on JSW's current business is posed by the regulatory and market transition risks inherent in the ambitious requirements to curtail emissions and the need for the transition and diversification of the business towards low-carbon technologies. The greatest potential positive impact on the JSW Group's current operations is exerted by the opportunities related to the development of energy generation sources allowing for energy self-sufficiency, as well as the potential to develop low- and zero-emission technologies.

Climate change may influence the Group’s operations through unfavorable, variable weather conditions which may contribute to disruptions in mining, production and supply of products to business partners and in supplies of materials to the Group’s plants required for the production process. Drought may have a particular impact, which will prevent water withdrawals for production purposes and the discharge of saline water to surface waters. In addition, higher temperatures in the summer may affect the ventilation and operation of mine workings' air conditioning systems. Coking plants, as continuous operation plants, i.e. production processes that cannot be stopped without destroying the facility, are particularly exposed to weather changes. The increased unpredictability of atmospheric phenomena, observed for several years, and the reduced distinctiveness of individual seasons have been identified as one of the significant climate risks.

In July 2022, JSW established a Climate Risk Committee to analyze identified climate risks and opportunities, develop or update existing risk charts in accordance with TCFD guidelines and the draft CSRD.

|

RISK* |

POTENTIAL NEGATIVE IMPACT ON THE GROUP |

POTENTIAL POSITIVE IMPACT ON THE GROUP |

POSSIBLE RESPONSE TO THE RISK |

|---|---|---|---|

| TRANSFORMATIONAL - TRANSITION | |||

|

Implementing the European Green Deal and the FIT FOR 55 Package |

|

Possibility of subsidizing/financing activities related to the development of a low-emission economy (RES projects and other pro-climate technologies) |

|

|

Increase in GHG emission charges and potential extension of the scope of the EU ETS to include methane |

|

Shift to low- and zero-carbon energy generation technologies |

|

|

Energy transition related to the EU climate policy |

|

Increase in demand for construction materials

|

|

|

Electromobility and development hydrogen technologies |

|

Increase in demand for hydrogen - an opportunity for the Group |

|

|

Demand for modern materials, transition to CE |

|

Development of new materials, e.g. carbon composites |

|

| PHYSICAL | |||

|

Increase in frequency of heat waves and drought periods; decrease in average summer precipitation |

|

Potential increase in demand for steel (coke),

|

|

|

Increase of extreme events (storms, winds, floods, fires) |

|

Cost attractiveness of products to European customers due to difficulties with overseas transportation

|

|

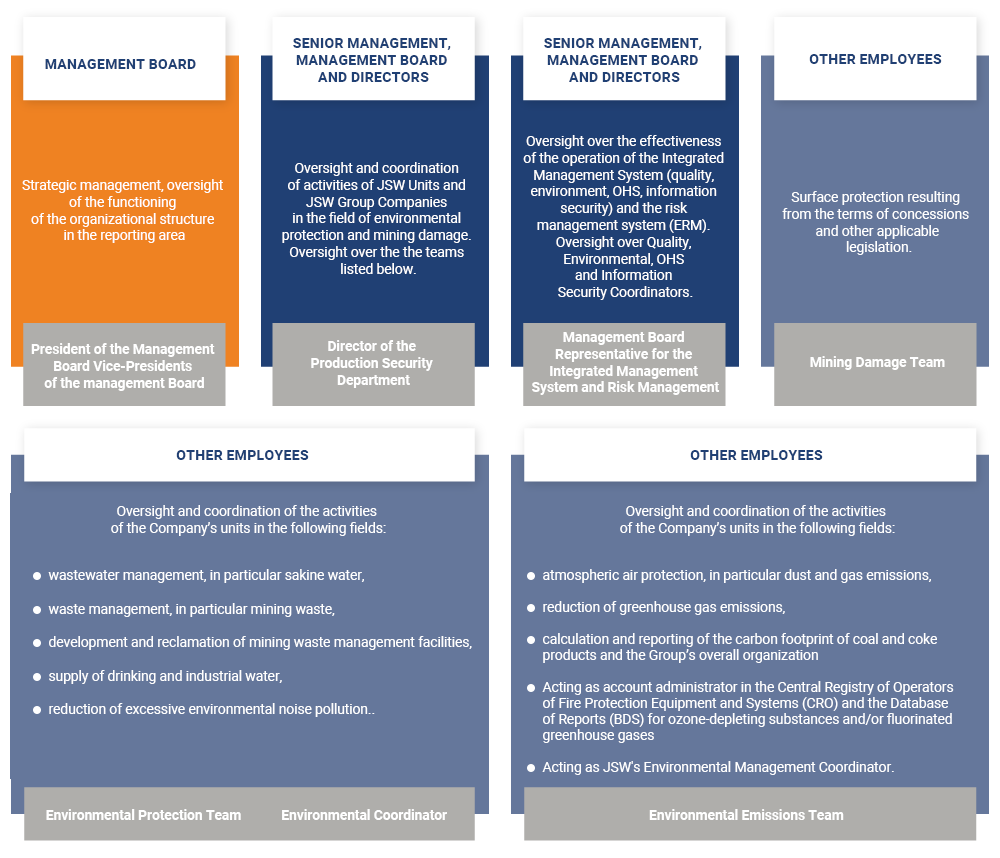

CLIMATE-RELATED ROLES AND RESPONSIBILITIES

As of 2018, all Group companies have designated individuals responsible for input data for carbon footprint calculations and environmental reporting. In the Parent Company, environmental issues are assigned to resources at the level of the Management Board, top management and other employees.

Structure of responsibility for environmental and climate protection in JSW:

COMMITMENT TO REDUCTION OF CLIMATE CHANGE

The current economic development policy of the European Union places particularly strong emphasis on climate issues, specified in the European Green Deal and ancillary documents, which in effect signifies the requirement to transition the industry towards a low-emission economy. As a producer of direct and indirect emissions of greenhouse gases in connection with the nature of our business and value chain, we are committed to the implementation of the objectives of the Paris Agreement and the European Green Deal. We are aware that our production processes cause high energy consumption and emissions into the air and water. We have to face these challenges in the near future and reduce them.

Since 2017, we have calculated the carbon footprint of the Group, which included direct and indirect greenhouse emissions involved in both the mining and coke production. The main source of greenhouse gas emissions from Group’s operations is methane, which is removed for safety reasons from mining pits (approx. 72% of the carbon footprint). The key to lower methane emissions is to capture it and exploit it commercially to generate energy.

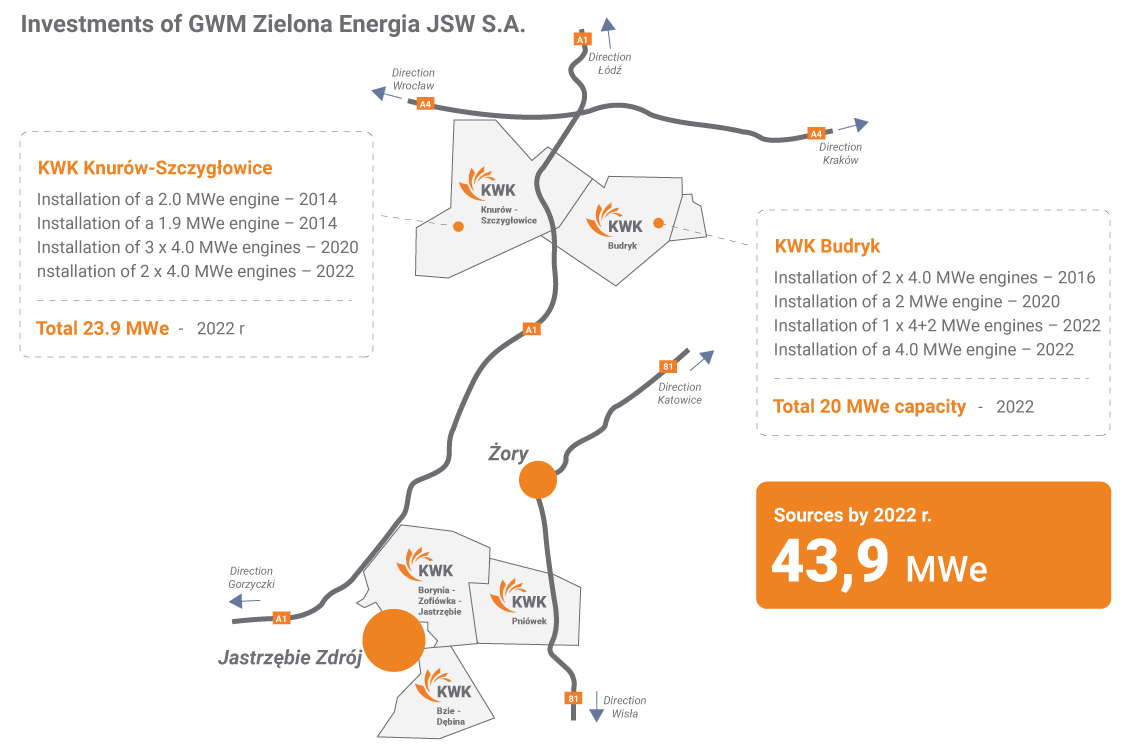

Since 2018, in KWK Budryk and KWK Knurów-Szczygłowice we implement an investment project entitled: “Commercial Methane Utilization” of the total project value of approx. PLN 300 million, designed to increase the share of in-house energy and reduce methane emissions and the carbon footprint by further 1.3 Mg CO2e.

The main source of greenhouse gas emissions from the Group’s operations is methane, which represents approx. 72% of the carbon footprint. In 2022, the methane emissions into the atmosphere were reduced by approx. 91 million m3, of which by approx. 23.5 million m3 in Q4 2022 alone.

In 2022, 168 thousand MWh of electricity was produced from methane (of which 98 thousand MWh was energy auto-production, the remaining volume represented purchases of energy generated from methane sold). In Q4 2022, the volume was 42 thousand MWh, including 20 thousand MWh of own production.

ACTIVITIES AND INITIATIVES UNDERTAKEN IN 2022

JSW has entered into a power purchase agreement for 2024-2025, which provides the opportunity to conclude and balance electricity under PPAs

JSW's Management Board established a Project Team to work out a concept for the development of its own RES capacity. As a result of the work of the Team, the JSW Management Board approved the Concept for the implementation of the PV farm construction program planned for implementation in 2023-2028

In July 2022, the Parent Company began reporting on climate issues for the first time and received a high grade in the renowned CDP rating. The survey revealed 103 Polish companies, of which only 16 received the highest grades of A to C. JSW, joining for the first time, received a high “C” grade and surpassed all companies in the mining industry.

JSW was ranked among the most climate-conscious companies in the fourth edition of the Company Climate Awareness Survey, which awarded JSW fourth place among 152 listed companies (the report evaluated was for 2021).

In 2022, within the Group, in JSW Ochrona and PBSz, photovoltaic panels with the total capacity of 0.08 MWp were installed. Currently, there are PV installations with the total capacity of ca. 0.86 MWp operating at the JSW Group.

JSW KOKS continued construction of a new power unit at the Radlin Coking Plant with a design capacity of 28MWe, which is to be powered by coke oven gas, and the electricity and heat produced will be used for its own needs and sold externally, thus reducing the Group's Scope 2 carbon footprint.

Both in JSW and other Group companies, projects were carried out to improve energy efficiency, including, among others: reactive power compensation, modernization of lighting, heating networks, heat exchangers, main drainage pumping stations, thermal modernization of buildings, installation of heat pumps, often correlated with the process of obtaining energy efficiency certificates (the so-called white certificates). In order to reduce the use of so-called F-gases, the modernization and expansion of central air-conditioning systems for underground workings is being successively implemented.

Carbon footprint

The Group is among the few groups in Poland that has been carrying out (since 2017) integrated estimation of the carbon footprint of the organization and two key products – coal and coke, based on the GHG Protocol standard using an implemented tool supporting the calculations. The calculations take into account emissions of the following greenhouse gases: carbon dioxide, methane and hydrofluorocarbons. The calculations were made in compliance with the GHG Protocol Corporate Accounting and Reporting Standard REVISED EDITION, based on energy supplier-specific (market-based) emissions intensity factors and GWP greenhouse gas creation factors published in the IPCC Fifth Report 2014 (AR5, The Fifth Assessment Report of the IPCC).

The scope of reported emissions (operational boundaries) includes scope 1 (scope 1, direct emissions) and scope 2 (scope 2, indirect emissions resulting from the generation of energy purchased by Group entities). Scope 2 emissions for all significant energy types were for the first time determined based on energy supplier-specific (market based) metrics.

| Scope 1 | Scope 2 |

|

Scope 1included direct emissions from sources located in all Group companies, comprising emissions:

|

Indirect emissions from scope 2 comprise emissions associated with generation of:

purchased and consumed by Group companies. |

The boundaries of reported emissions (organizational boundaries) include the Parent Company and all Group companies according to operational and financial control - 100% of emissions from all Group companies. No biogenic emissions were recorded in 2022.

The JSW Management Board decided to publish information on the organization’s carbon footprint. The carbon footprint of coal and coke products calculated in scopes 1, 2 and 3 upstream will be made available on the express request of the Group’s business partners for such products

|

ORGANIZATION’S CF GROUP |

TOTAL EMISSIONS (SCOPE 1+2) |

||||||

|---|---|---|---|---|---|---|---|

| DIRECT EMISSIONS (SCOPE 1) |

INDIRECT EMISSIONS (SCOPE 2) LOCATION BASED |

EMISSIONS PER PRODUCT UNIT (COAL+ COKE) |

EMISSIONS PER PLN 1 MILLION OF REVENUE |

||||

| YEAR | mt OF CO2e | CO2 | CH4 | HFCs | m Mg/m Mg | m Mg/m PLN | |

| 2017 | 8,10 | 1,06 | 6,03 | 0,01 | 1,00 | 0,456 | 0,000912 |

| 2018 | 8,22 | 1,10 | 6,05 | 0,02 | 1,05 | 0,447 | 0,000838 |

| 2019 | 7,92 | 1,05 | 5,63 | 0,02 | 1,22 | 0,443 | 0,000914 |

| 2020 | 7,18 | 1,13 | 5,32 | 0,02 | 0,71 | 0,406 | 0,001027 |

| 2021 | 7,92 | 1,29 | 5,86 | 0,01 | 0,76 | 0,456 | 0,000745 |

| 2022 | 7,58 | 1,12 | 5,47 | 0,02 | 0,97 | 0,440 | 0,000375 |

Base year 2017 recalculated according to new emission factors for purchased energy (market-based).

Boundaries of the organization – approach to operational control – 100% of emissions from all Group companies

Operational boundaries – direct and indirect emissions in scopes 1 and 2 Due to the fact that both coal and coke constitute intermediate products in further processes, scope 3 in the organization’s carbon footprint was omitted.

In accordance with the methodology recommended by the GHG Protocol, uncertainty of the organization’s carbon footprint was set at 8

To assess the level of emission intensity, the ratio of greenhouse gas emissions per unit of product (the sum of coal and coke production) and per unit of revenue is used at the Group level.

JSW GROUP’S CARBON FOOTPRINT 2022

GHG EMISSIONS FOR 2022 BY CATEGORY

In 2022, the JSW Group’s total emissions within scopes 1+2 dropped by 6.4% compared to the 2017 base year, with emissions from scope 1 decreasing by 7% and emissions from scope 2 decreased by 2.6%. Compared to 2021, there was a significant decrease in direct emissions of both CO2 by 13.2%, resulting from an increase in coke production, and a decrease in methane emissions by 6.6%.

Gas and dust emissions

The main source of greenhouse gas emissions following from the Group’s operations is methane from the ventilation of mining pits (approx. 72% of total emissions, converted into CO2e) and carbon dioxide from fuel burning processes, mainly in the coke segment. Curtailing greenhouse gas emissions in the Group was accomplished by making the maximum energy utilization of gas through methane drainage in the mines. As a result of utilization of captured methane for production of electricity and heat in high-efficiency cogeneration systems, in 2022 the emission of methane into the atmosphere was reduced by approx. 90.9 million m3.

In the coke segment, execution of the strategic projects launched in 2019 – modernization of the coke oven battery in the Przyjaźń Coking Plant and construction of a power unit in the Radlin Coking Plant – will make it possible to maximize the use of coke oven gas and improve energy efficiency. Excess coke oven gas is used for production of electricity and thermal energy for internal use and for sale.

Other atmospheric emissions

Other substances emitted mainly as a result of: burning of fuel in boilers, gas engines, combustion engines in means of surface and underground transport and machinery and equipment do not cause breaches of the permissible levels or benchmarks. In 2022, two tasks important to JSW KOKS were completed:

- Flue gas denitrogenation - 71 MW unit at the Przyjaźń Coking Plant,

- CDA and SRCM (KRAiC) installation – construction of the 2nd line with an acid absorption column in the Radlin Coking Plant.

| OTHER EMISSIONS (GROUP) (Mg0 | 2022 | 2021 | GROWTH RATE 2021=100 |

|---|---|---|---|

| MASS OF OTHER SIGNIFICANT ATMOSPHERIC EMISSIONS, INCLUDING: | 7 641,4 | 8 244,6 | 92,7 |

| SOx | 1 624,5 | 1 846,3 | 88,0 |

| NOx | 2 852,2 | 3 001,2 | 95,0 |

| CO | 2 696,6 | 2 926,7 | 92,1 |

| Total dust | 468,1 | 470,4 | 99,5 |

| OTHER ATMOSPHERIC EMISSIONS PER UNIT OF REVENUE – MG/PLN M | 0,38 | 0,78 | 48,7 |

Fuel and Energy consumption

FUEL CONSUMPTION FOR ENERGY PRODUCTION IN THE GROUP

| ITEM | 2022 | 2021 | GROWTH RATE 2021=100 |

|---|---|---|---|

| Motor gasoline (liter) | 271 631,6 | 257 833,0 | 105,4 |

| Diesel fuel (ON) (liter) | 9 521 613,0 | 9 962 426,3 | 95,6 |

| LPG (liter) | 67 294,1 | 46 337,3 | 145,2 |

| Gas from mine methane drainage (m3) | 25 206 300,0 | 36 284 600,0 | 69,5 |

| Coke oven gas (m3) | 1 115 123 472,0 | 1 280 948 592,3 | 87,1 |

| Heating oil (Mg) | 397,2 | 146,8 | 270,6 |

| Hard (steam) coal (Mg) | 568,5 | 394,0 | 144,3 |

| Waste gas fuel (excess gas) (GJ) | 11 238,5 | 45 473,8 | 24,7 |

| Natural gas (m3) | 192 646,0 | 452 328,2 | 42,6 |

ENERGY CONSUMPTION

| ENERGY CONSUMPTION IN THE GROUP | 2022 | 2021 | GROWTH RATE 2021=100 |

|---|---|---|---|

| ELECTRICITY (MWh) | |||

| Production | 717 998,0 | 949 031,1 | 75,7 |

| Purchase | 1 117 895,3 | 1 496 136,1 | 74,7 |

| Own consumption | 1 479 365,6 | 1 519 970,3 | 97,3 |

| sale | 355 970,2 | 924 582,1 | 38,5 |

| HEAT (STEAM, HOT WATER) (GJ) | |||

| Production | 1 752 438,0 | 1 903 168,0 | 92,1 |

| Purchase | 1 453 592,0 | 1 598 918,0 | 90,9 |

| Own consumption | 3 198 604,0 | 3 469 989,0 | 92,2 |

| Sale | 7 426,0 | 32 097,0 | 23,1 |

| COOL AIR (GJ) | |||

| Production | 220 320,0 | 218 210,0 | 101,0 |

| Purchase | 211 144,0 | 230 804,0 | 91,5 |

| Own consumption | 431 464,0 | 449 014,0 | 96,1 |

| Sale | - | - | - |

| ENERGY CONSUMPTION IN JSW | 2022 | 2021 | GROWTH RATE 2021=100 |

|---|---|---|---|

| ELECTRICITY (MWh) | |||

| Production | 98 179,4 | 140 883,9 | 69,7 |

| Purchase | 1 021 637,3 | 994 125,3 | 102,8 |

| Own consumption | 1 112 113,2 | 1 125 585,3 | 98,8 |

| Sale | 7 703,5 | 9 418,2 | 81,8 |

| HEAT (STEAM, HOT WATER) (GJ) | |||

| Production | 24 441,0 | 26 424,0 | 92,5 |

| Purchase | 862 274,0 | 955 578,0 | 90,2 |

| Own consumption | 886 715,0 | 982 002,0 | 90,3 |

| Sale | - | - | - |

| COOL AIR (GJ) | |||

| Production | 220 320,0 | 218 210,0 | 101,0 |

| Purchase | 211 144,0 | 230 804,0 | 91,5 |

| Own consumption | 431 464,0 | 449 014,0 | 96,1 |

| Sale | - | - | - |

Methane and its utilization

Coal mining is inextricably linked to the production of a by-product such as methane. The rich reserves of this material in Poland offer the opportunity of significant economic benefits, increased safety in mines and the implementation of the national strategy, which assumes further development of circular economy, in which by-products of one process are used commercially for another one.

In 2022, the methane emissions into the atmosphere were reduced by approx. 91 million m3, of which by approx. 23.5 million m3 in Q4 2022 alone.

In 2022, 168 thousand MWh of electricity was produced from methane (of which 98 thousand MWh was energy auto-production, the remaining volume represented purchases of energy generated from methane sold). In Q4 2022, the volume was 42 thousand MWh, of which 20 thousand MWh constituted own production.

Since 2021 JSW has operated a special website about methane and its commercial utilization in the company’s units. The information presented on the website concerns actions taken by JSW with a view to reducing methane emissions into the air. Its intended readers are decision-makers and opinion leaders, both in Poland and across Europe, involved in issues related to efforts aimed at reducing methane emissions.

For more information, see here.

METHANE EMISSIONS IN 2022

Release of methane in the mining process

Chart. Total volume of methane released in the coal mining process in JSW S.A. mines in 2022 [million m³ CH₄]

Utilization of captured methane

Chart. Volume of methane captured in surface methane drainage stations in 2022 [million m³ CH₄]

The main source of greenhouse gas emissions from the Group’s operations is methane, which represents approx. 72% of the carbon footprint. Taking into account the assumptions of the Environmental Strategy and the adoption of GHG reduction targets aligned with the Paris Agreement, we are undertaking numerous initiatives to achieve the assumed targets:

COMMERCIAL METHANE UTILIZATION PROGRAM

The Commercial Methane Utilization project had been planned for years 2018-2023 and entails the utilization of methane from the Budryk Mine and the Knurów-Szczygłowice Mine and the production of energy to be used by these mines and subsequently by other JSW mines. The objective of the project is to develop the infrastructure that will enable JSW to generate electricity by burning excess methane from the methane drainage process at the mine.

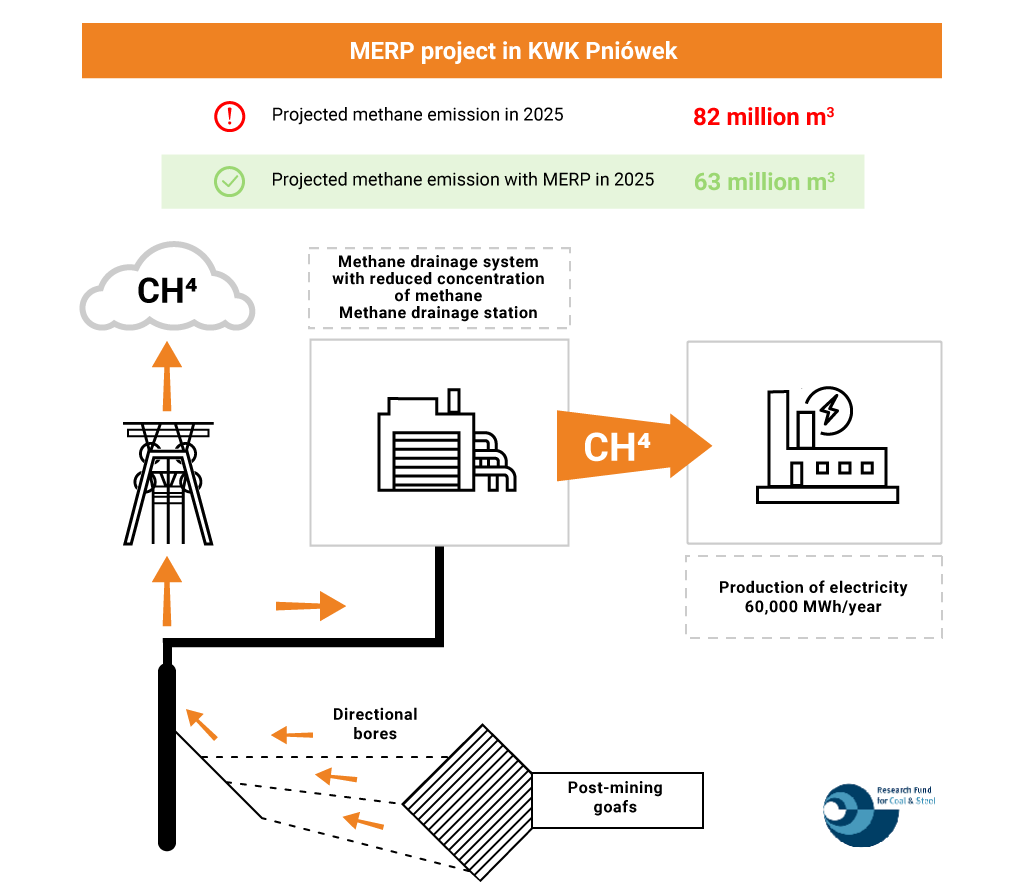

METHANE EMISSION REDUCTION PROGRAM

The Methane Emissions Reduction Program (MERP), which covers all the mines, incorporates the commercial methane utilization program that has been pursued to-date as well as new efforts needed to achieve the intended level of reduction of methane emissions. The MERP program has adopted two lines of action:

- reduction of methane emissions into the ventilation air and thus into the atmosphere through ventilation shafts by actions taken directly in the underground workings, increasing the capture of methane through the methane drainage system. Assumed achievement of the methane drainage efficiency of JSW mines at > 50%.

- strive for complete utilization of the methane captured by the methane drainage system. Adopted methane utilization rate of >95%. The direction adopted is a continuation of the Commercial Methane Utilization (GWM) program in the northern mines extended to the southern mines. There are plans to modernize and build a methane drainage station and build more cogeneration systems. Upon completion of the program, the total installed capacity of the company's own CHP systems will be approx. 60 MWe.

The implementation of the entire methane emissions reduction program with the estimated value of approx. PLN 300 million by 2025 (including PLN 122 million included in the current business model) will enable the reduction of greenhouse gas emissions, expressed as carbon footprint, by about 24% by 2026. This is due to lower direct emissions of methane as well as emissions due to energy purchased from outside sources.

W, as the lead partner of a consortium consisting of scientific and research institutes affiliated jointly with JSW in the ICE-CMM Mine Methane Center of Excellence, has succeeded in obtaining funding of EUR 11 million for the Methane Emission Reduction project (MERP). The budget for the entire project is nearly EUR 22 million. Thanks to the involvement of the Central Mining Institute, it has been possible to attract foreign partners, research centers from Romania and Spain, to cooperate. The methane extracted from post-mining goafs will be used to produce electricity in gas engines connected to power generators. The project will reduce methane emissions by 19 million cubic meters per year and produce 60 thousand MWh of electricity in the methane utilization process.

MASTERMINE PROJECT

This is a research and implementation project carried out by JSW and the Central Mining Institute. The project has received funding under the European MASTERMINE program from EU’s Horizon Europe research fund.

The project aims to optimize and improve the efficiency of the mine's methane drainage system through its automation and digitization. As a result the capture of methane released during mining will be more effective. This will improve the safety of mining crews and reduce methane emissions, as less of this hazardous gas will migrate into the atmosphere with ventilation air.

The implementation of the smart methane drainage system at the Pniówek mine will begin with an inventory-taking of the methane drainage network. Thorough work will then be carried out to study and determine its parameters. Based on this, Central Mining Institute specialists will design a new network of sensors and control devices. New algorithms will be developed for the system, which will allow the system to operate autonomously and fully automatically, without the need for constant operator supervision.

A consortium of 22 entities (including 2 from Poland) is involved in the project.

VISUALIZATION OF THE METHANE DRAINAGE NETWORK

The underground methane drainage network consists of many kilometers of pipelines, through which methane from capture sites is transported to the surface. The pipelines are under negative pressure generated at the methane drainage station located at the surface of the mine. In order to ensure the correct regulation of gas capture and flow, measurements are made on a daily basis on the main pipelines as well as inside the areas where methane is captured. Currently, the measurements are made manually by certified employees (metering technicians) once per 24 hours.

The project of visualization of the underground methane drainage network covers the main methane pipelines in all JSW S.A. units. It consists of 60 metering points where methane concentration in the captured gas, depression, temperature of the captured gas and flow rate will be measured automatically. This data will be sent to the surface online and, through the central data analysis system, will be available for the personnel responsible for the methane drainage process.